The Z-Fact0r was born in 2016 under the initiative Horizon 2020, it’s duration is 42 months and is divided into four phases which include the following types of activities: R&D, Integration and Validation, Demonstration activities, Standardization and Business Modelling, Dissemination, Exploitation and Communication and Project management. Z-Fact0r has also brought together a total of 13 EU-based partners, representing both industry and academia, having ample experience in cutting-edge technologies and active presence in the EU manufacturing.

Manufacturing represents approximately 21 % of the EU’s GDP and 20 % of its employment, providing more than 30 million jobs in 230 000 enterprises, mostly SMEs. Moreover, each job in industry is considered to be linked to two more in related services. European manufacturing is also a dominant element in international trade, leading the world in areas such as automotive, machinery and agricultural engineering. Already threatened by both the lower-wage economies and other high-tech rivals, the situation of EU companies was even made more difficult by the downturn.

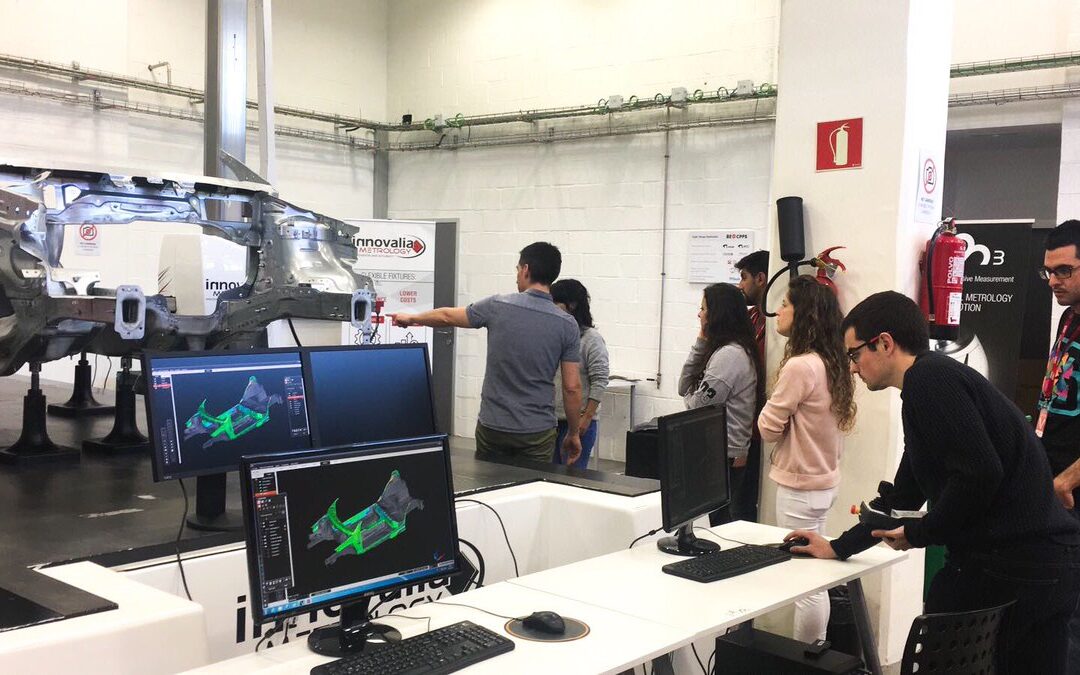

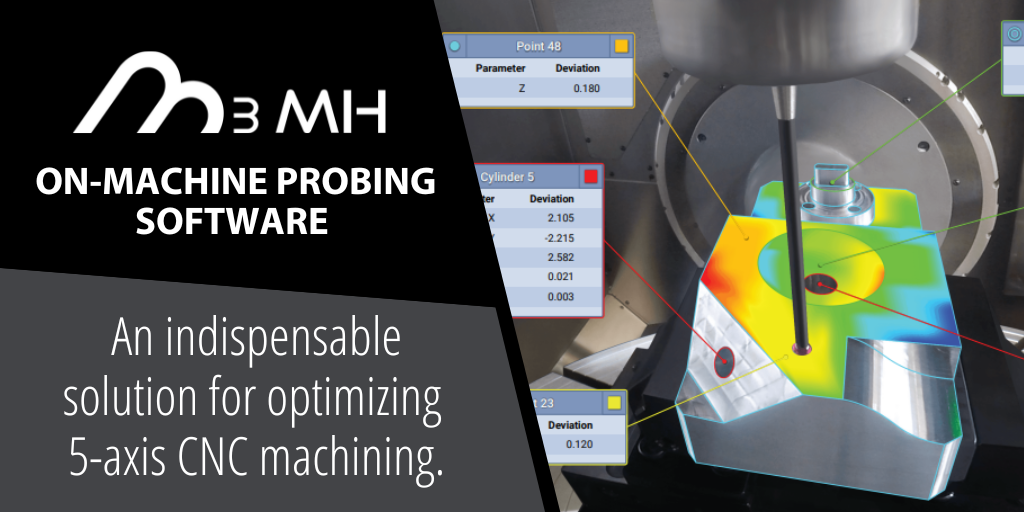

Datapixel, will give support to the project through their advanced scanning technology and algorithm creation. The scanning technology will give information about the production quality and the algorithms will make the error detection and assignation very quick and automatic. This way, the production system will identify within minutes the errors in the parts and will be able to fix them.

The Z-Fact0r consortium has conducted an extensive state-of-the-art research and realized that although a number of activities have been trying to address the need for zero-defect manufacturing, still there is a vast business opportunity for innovative, high-ROI (Return on Investment) solutions, that will ensure better quality and higher productivity in the European manufacturing industries through 4 phases:

Phase 1: Technology generation and experimentation: This phase of the project includes all the R&D activities for the development of Z-Fact0r subsystems.

Phase 2: Integration and validation of the technologies from Phase 1: This phase involves all the integration activities that will be performed during the Z-Fact0r project. The goal of this phase is to prepare the system for its validation as a full prototype. Each subsystem will be fine-tuned with the rest, and minor modifications are expected in order to optimise all the subsystems to operate as a single integrated system.

Phase 3: Demonstration of the Z-Fact0r results from Phase 2. The validation activities from Phase 2 will offer vital input to make any necessary adjustments before deploying the system in the real industrial use-cases. The first step is the demonstration of the validated technologies in the use-cases while the ultimate one is the Z-Fact0r prototype demonstration in the operating environments. The accumulated results will give feedback to Phase 2 in order to monitor the required actions and perform an evaluation of the KPIs.

Phase 4: Project Management and Dissemination, Exploitation, and Communication Activities: This Phase runs the whole duration of the project in order to keep track of all the involved activities (R&D, DEMO) and take action when is required. This will ensure the smooth progress of all the R&D and demonstration activities as well as efficient planning for commercialisation and dissemination of the results throughout the duration of each phase.

The Z-Fact0r Project, thanks to each phase will be able to introduce predictive and preventive systems to ensure a better production quality in the European Industry.